|

The

PLT-1 Replacement Pulsar LED Module Development

By Ben Azari, Pulsar LED Time &

Army Radio Sales Co.

|

|

A long time ago when the original Star

Trek and Kojak TV shows were running and people were going to the moon, I

was not even a teenager.

I was walking back home one day from school, I saw for the

first time a fantastic new watch, the likes of which I had never seen

before. It had a gold metal case and strap and a mysterious dark window

which reminded me of an Astronauts visor that we were frequently seeing on

TV back then. The thing looked like something from outer space!

Picking up courage, I walked in to the jewellers shop and asked the man

about this mysterious watch in the window. Can I have a look at that strange

watch in the window please, is that a watch, I asked! |

He took a long look at me. Probably thinking to himself, here we go another

time waster! He handed me one from under the counter saying be careful don’t

drop it, they have just come out, it has a LED. Huh what?

The moment I had it in my hand I knew

I wanted it. It was big. And it was heavy. He said go on press the button on the

side. The dark window lit up showing actual numbers in bright red light, wow

is that the time? I asked, yes he said and if you hold the button you will

see the seconds.

This was the most impressive thing I had ever seen. So cool, wow a digital

watch! I could see the time as red coloured numbers which change in real

time in front of my eyes as the seconds tick away, like a dance of numbers I

can watch all day and even at night! By now I wanted it more than anything else

in the whole world and wondered how it worked.

I asked the Jeweller the price, he said, son, this costs more than you will

ever be able to afford and told me the price. He said he had cheaper models

of the same type watch with red display made by Pulsar and Hamilton, but I

wanted the one in my hand, this was the watch for me. |

|

The numbers he said didn’t really mean much to me and I

said thank you, I will ask my dad. He was laughing and said I am sure he will

buy it for you…

The difference between the watch brands was unknown to me at the time.

Apparently I had good taste even at that young age and had picked one of the

more expensive brands on the market. At least it wasn't solid gold!

|

|

|

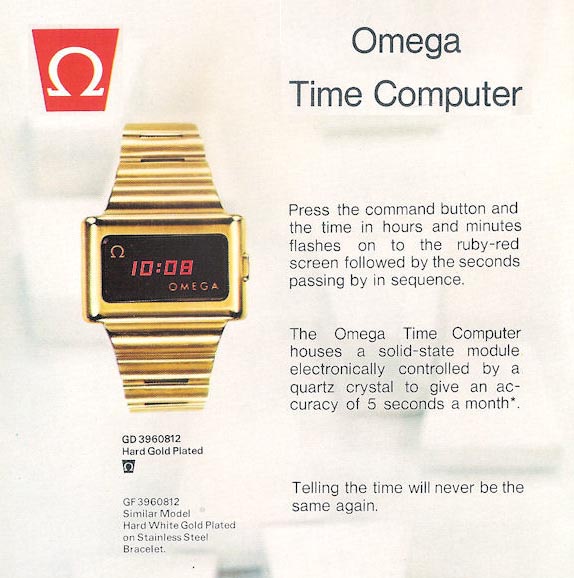

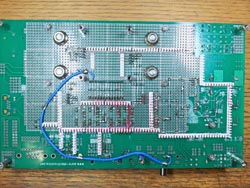

1974 Omega Sales

Leaflet Showing a Time Computer TC1 Watch

"Telling Time Will Never Be The Same Again" |

I wrote down the details, Gold Skin Omega TC1 LED Time

Computer watch and ran home to tell my dad.

My dad was still at work and I couldn’t wait for him to come home so I picked up

the phone and called him, dad, dad, dad, I saw this fantastic new watch today,

you have never seen anything like it. There is a button at the side and when you

press it the time is shown in numbers and the numbers are red light and you can

see it though a dark window, you see the numbers change….. He said he is busy

and will speak about it when he gets home later.

|

|

|

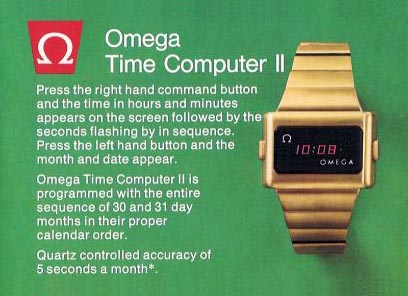

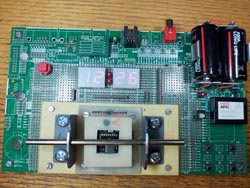

Omega Sales

Leaflet Showing a Time Computer TC2 Watch |

I was really disappointed when he came home later that

day and tried to explain to me why we could not afford it. Despite working for an oil company he said he will have to work

for a whole year and save all the money to buy the watch. I didn’t think that

was a problem but he thought it was!

I offered to do work around the house, wash

the car every day and be good at school and not to fight with my sister, but he

said no and that was the end of that!

Soon these Light Emitting Diode LED watches disappeared from the shops and were

replaced with cheaper Liquid Crystal LCD Display watches from Japan. My dad

eventually got me a Casio LCD watch and I was happy with that, at least it was

digital.

|

Probably seeing that Omega watch back then was the contributing factor setting

me off in my future life in electronics. Years passed, with my hair now going

grey and heavy in to electronics, engineering, computers and software design,

that Omega Time Computer watch was just a distant memory from my childhood.

It was eight years ago while sitting in the office pretending to be working, but

really surfing the internet killing time like one does, I came across the exact

type of Omega watch I had seen some 40 years earlier in that shop window.

I had to have it, this time price not a problem. It was being sold as un-tested

the seller said he could not open the back to try batteries, really! Being in to

electronics and having all the tools and instruments necessary to work with

small SMD devices I did not think that was a problem and I bought the watch

anyway. |

Once it arrived and I had it in my hand the memories came flooding back, I

remembered the jeweller laughing and saying you will never afford one. Who is

laughing now I thought…

I had to try it out and get it going. Got the back off the watch and what I saw

was a complete mess! The original but now obsolete large 355 batteries were

still installed in the watch and after so many years they had leaked badly

corroding the module and circuit board.

|

|

|

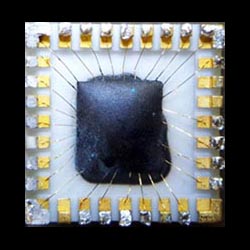

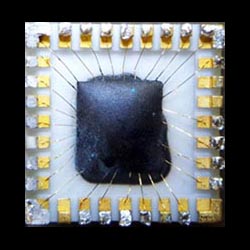

Example of a Corroded Pulsar Module |

View of a Pulsar Time Computer IC |

I cleaned and repaired the damaged tracks on the circuit board and sort of got

the module half running. The black paint covering the entire module and circuit

board is awful, when mixed with the battery acid it gets sticky and it’s hard to

clean. One of the problems was the oscillator circuit which was not oscillating.

Feeding the module with an external 32.768 KHz clock signal got the module

temporarily running.

The other problem was that not all the segments of the display were lighting up.

One of the missing segments was traced to a bad driver transistor, which was

fixable but the other dead segments were traced back to the chip it self, not

good!

Removal of the chip revealed more corrosion underneath. Viewed under a

microscope, one of the bonding wires going the leg of the chip looked eaten

away. There was no way I could fix this. Damn!

There was hardly any info on these watches on the internet back then. I was more

than determined to get the watch working. Then I found out that the same exact

modules are used in other watches made by Pulsar and Hamilton. Omega did not

make the modules them self’s but bought them in from Pulsar and installed them

in to their own case.

Spare parts and modules for these watches have long been obsolete and none are

available. The only way to get parts is to remove parts from other scrap

modules. So I bought a few more non working watches of Pulsar and Hamilton types

having various faults and reversed engineered them to learn all I could. These

old Pulsar dot pattern LED displays or as some people wrongly call them dot

matrix LED watches were a marvel of modern technology back then and I liked the

way they were constructed.

I got pretty good fixing them and started fixing them for other people. But

unfortunately too often the watch module was beyond repair and to the owner’s

disappointment I had to return them un-repaired.

This got me thinking that it was very rare for one of these pulsar LED modules

to have a faulty LED display or bad magnetic reed switches, it’s usually the

rest of the circuit that has a problem, something like a bad chip or corroded

circuit board would normally write off the watch as un-repairable, which was a

shame.

Spare parts are no longer available and I don’t think that even back then you

could go and just buy the chip off the self. I am sure Pulsar would sell you a

brand new module instead, but sadly even these are no longer available.

|

The only logical way out of this situation was to build a replacement module

from scratch using modern components to function exactly like the original

Pulsar LED watch module. Then with this new replacement module I will be able to

remove the original Pulsar LED display from the faulty module and re-use it

along with the original plastic carrier and micro reed switches on the new

module.

The end results would be a working watch using the original dot pattern LED

display. It would look and work like the original Pulsar watch. |

Now here is a dilemma, I like to keep things 100% original and a watch which is

all original and working is obviously a better bet, but given the choice between

a dead un-repairable watch which is 100% original to a working watch which is

80% original I will leave you to decide.

I decided to go ahead with the project and make a prototype, sort of proof of

concept.

Code name for the project was PLT-1, which stands for “Pulsar LED Time“ and the

1 because it’s the first module of hopefully many!

Work progressed slowly, I was far too busy at work, and then our first child was

born which took up what ever free time I had left.

At this point a friend came on board and offered to help out with some of the

core software which was to run on the modules.

It was decided from the onset of the project that this module should not only be

as good as the original Pulsar module, but be better than original!

It should be able to do more things than the original ever could, after all

almost 40 years have passed and technology has moved on.

The final look of the circuit board was un-important to me. I was not going to

copy the thing for its looks. The new module is never going to be the original

module, so why restrict your self by using components that try to mimic the

original look instead of the best components for the job.

|

|

One Button Standard

Mode

PLT-1 LED Watch Module |

Two Button Standard

Mode

PLT-1 LED Watch Module |

The new module also had to be two modules in one. It should work exactly like

the original module out of the box and function like a single button time only

watch or a dual button time and date watch. The new PLT-1 replacement Pulsar LED

watch module replaces the modules in the following watches.

Pulsar P2, Module #2900 Single Button Time Only LED Watch.

Pulsar P3, Module #3013 Dual Button Time and Date LED Watch.

Hamilton QED Module #995 Single Button, Time Only LED Watch.

Hamilton QED Module #955 Dual Button, Time and Date LED Watch.

Omega TC1, Time Computer 1, Calibre 1600, Single Button, Time Only LED Watch.

Omega TC2, Time Computer 2, Calibre 1601, Dual Button, Time and Date LED Watch.

Originally I intended to have

factory settable links to set the mode, but later it was decided to put the

owner of the watch in charge and have the mode selecting done through the

configuration menu.

It was also decided to include two additional user settable modes to enhance the

functionality of the original watch beyond what Pulsar ever intended to!

|

|

One Button Enhanced

Mode

PLT-1 LED Watch Module |

Two Button Enhanced

Mode

PLT-1 LED Watch Module |

Other features that we came up with were the user settable display time out

timer, user settable display brightness level adjustment, a low battery warning

system and display segment test.

Another area of the original module which could do with improvements was with

accuracy. So for our new module we choose one of the best high precision

flexural tuning fork Quarts Crystal available. The Crystal is hermetically

sealed in a ceramic package and has a accuracy of +/- ten parts per million. The

crystal oscillator is then trimmed and calibrated via software. This should be

much more accurate than the original Pulsar module.

We also decided to make the gold plated circuit board of the new modules from a

highly durable glass fibre material and chose black for its colour. The original

modules were covered in black paint. I do not like it. It’s unprofessional and

looks awful.

The reason for the black paint was that the original module used a Ceramic PCB

that was white in colour and incidentally sometimes prone to cracking. Most of the components

mounted on that board were also white in colour and it all showed through the

dark window of the watch. Pulsars solution was to cover everything with black paint!

Instead we choose a black coloured circuit board to minimize the problem and

make the new circuit boards nice and tidy.

|

|

|

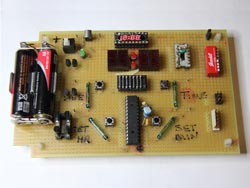

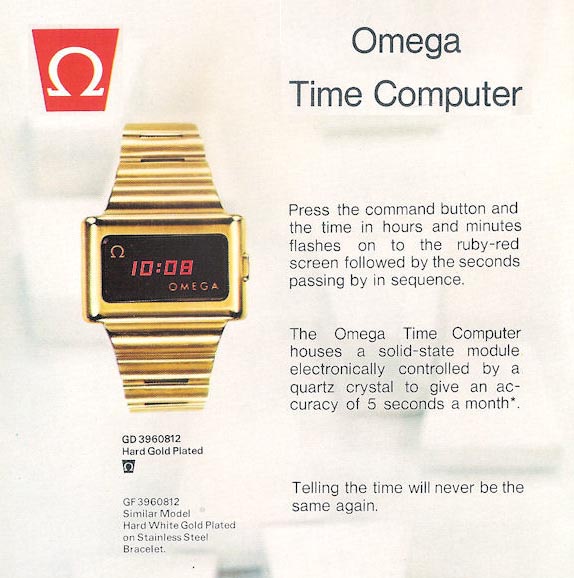

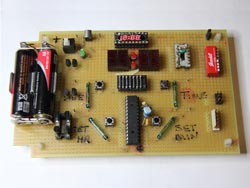

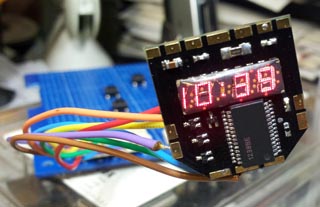

The First Rough Prototype of PLT-1 |

The Updated PLT-1 Prototype |

Eventually after a few slow years and a few revisions

and software updates later we had a good stable

working prototype. With the hardware now fixed I could concentrate on

miniaturisation, circuit board design and software development of the new PLT-1

module.

With the core software which was written by my good friend Gerry Sweeney

"His Website Here" now

running on the crude prototype board, we were able to get the basic functions of

a watch running.

There was still a long way to go in regards with the

software, but I was happy that making a new replacement Pulsar LED watch module

was possible.

I built the first prototype using large components that I could see and handle

easily. Next step was miniaturisation to fit all the components on to a circuit

board with the same dimensions as the original Pulsar circuit board.

Certain aspects of the new circuit

board were fixed, like it's size, position of the LED display and the pads

that would connect to external components such as the magnetic reed switches

and power lines.

The design of the circuit board progressed along side the first prototype

board. As the hardware was being tweaked the improvements were reflected

back to the circuit board. Finally, In October 2012 I ordered the

first batch of PCB's to be manufactured. |

|

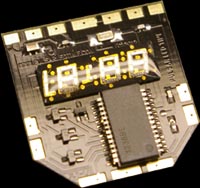

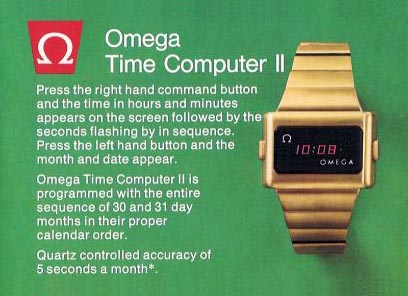

The PCB's arrived and they looked perfect,

exactly matching the size of the original board!

|

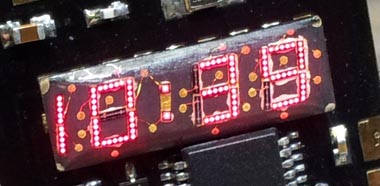

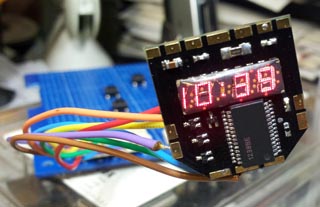

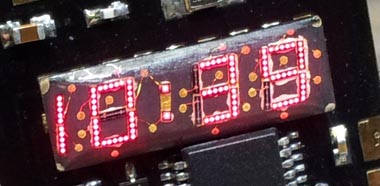

The first PLT-1 module was then assembled on to the PCB and crudely wired up

to a set of switches to replicate the magnetic reed switches of a watch, it was then programmed with the core software

and it sprung to life!

The new PLT-1

replacement module was a

complete success!, We now had a working board driving the original LED

display, rescued out of a old broken Pulsar LED watch.

Left hand picture shows the first ever running PLT-1 module. The

Replacement LED Module for the Omega, Pulsar and Hamilton LED Watches. |

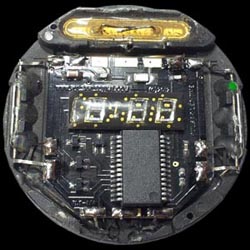

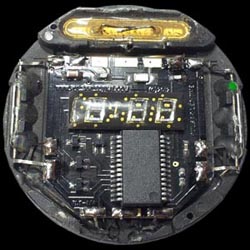

Two boards were then fully assembled

and installed in to two Omega TC2 Time Computer watches that we would

wear for everyday use and test out.

|

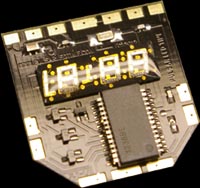

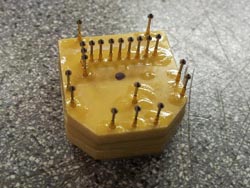

Next step was to construct a proper test jig to take the assembled circuit board

for testing and programming.

The PLT-1 circuit board was designed from the onset to be quickly and easily

programmed, tested and calibrated without actually having a display

installed or any soldered wire connections to the completed circuit board.

Special test pads were included on the circuit board design to facilitate

this.

These test pads would connect up to gold plated spring loaded pins when the

completed board is placed in to the test pod. These pins would in turn

connect up to an external display and switches on the test jig.

Left hand picture shows a fully assembled PLT-1 LED watch module installed

on the original pulsar plastic carrier ready to be installed in to a watch. |

The following photos show the construction of the test

pod for PLT-1 circuit board and the test jig.

|

|

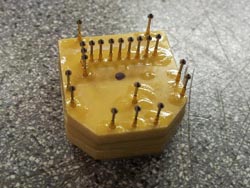

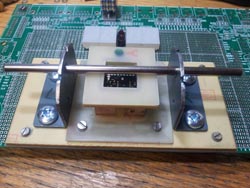

PLT-1 Test Pod Construction

Spring loaded test pins |

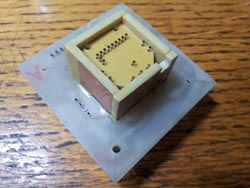

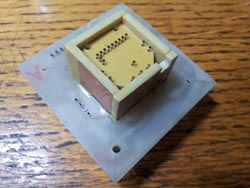

PLT-1 Test Pod Construction

Circuit Board Enclosure |

| |

|

|

|

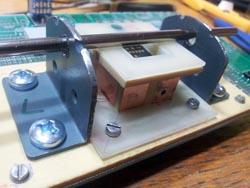

PLT-1 Test Pod Construction

Base Plate Top Side |

PLT-1 Test Pod Construction

Base Plate Bottom Side |

| |

|

|

|

PLT-1 Test Pod Construction

Top Pressure Plate |

PLT-1 Test Pod Construction

Reinforcement Plate |

| |

|

|

|

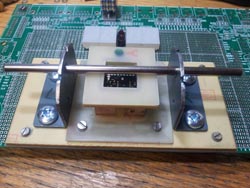

PLT-1 Test Pod Construction

Top Pressure Plate Holders |

PLT-1 Test Jig Construction

Test Pod Installed |

| |

|

|

|

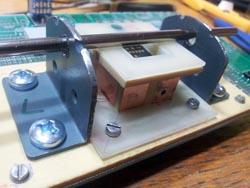

PLT-1 Test Jig Construction

PCB Board in Test Pod |

PLT-1 Test Jig Construction

Test Pod |

| |

|

|

|

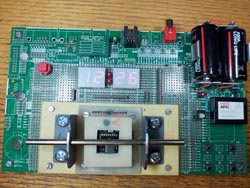

PLT-1 Test Jig Construction

It's Almost Finished |

PLT-1 Test Jig Construction

Its Alive |

| |

|

|

|

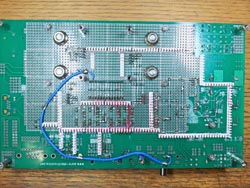

PLT-1 Test Jig Construction

Top Side |

PLT-1 Test Jig Construction

Bottom Side |

| |

|

|

|

PLT-1 Test Jig Construction

Completed Test Jig |

A Load of Completed

PLT-1 Pulsar LED Watch Modules |

Now with the completed test jig I was easily able to get

a completed PLT-1 module with-out the display or reed switches attached, put it

down on the test pod then close the pressure plate and program the device. The

much larger LED display and switches are mounted externally on the test jig.

At this stage the core firmware running on the new module was the bare minimum

needed to get the module running. It could do the basic functions of a digital

watch and had a few minor bugs to iron out, there was still a long way to go.

Even though the module now worked like a digital LED watch it did not behave

like a Pulsar watch. Now I had to program in the way the original Pulsar LED

watch behaved when the buttons where pushed and what displayed on the LED

Display.

This is not as simple as one may think. There are so many fine points to this,

first of all the way the buttons work and interact together. Normally pressing

time button would display the time, but that's not the end of it. You have to

program in various key combinations, for example what happens if one presses the

Time and then the Date Buttons together, or what happens if the Time button is

pressed first then the Date button, or what if the Set Minute and Set Hour are

pressed together and then the Date or Time Button. You get the picture.

All these key combinations and behaviour had to be programmed to exactly mimic

the original functions of a one or a two button Pulsar watch. Now we had two of

the standard operating modes of a single button or a double button Pulsar watch. Next step was to program in the Enhanced modes of operation which would

allow the watch to do more than it could originally. Using the enhanced mode a

single button watch which could only tell the time would now be able to display

not only the time but the date, year and weekday.

Over the next few months the configuration menus and extra features like the

display test, variable display time out, Display brightness adjustment were

added to the firmware of the module and tested.

|

|

Finally by March 2013, some 5 years

after the start of the PLT-1 project, it is finished!

I must say that I am very proud with what we have created. We have created

something magical. A hybrid. A marriage of almost 40 year old technology and

the latest modern technology. With these new PLT-1 replacement LED watch

modules, these fantastic old retro Pulsar, Omega and Hamilton watches with

the magical dot pattern LED displays should live for another 40 years if not

more.

I like to think in the years to come, maybe some time in the next century and

long after I am gone, some one will be making replacement modules to replace the ones

I have been making to keep these watches going for ever. |

I can not describe the satisfaction I get every time I

press the button on my watch and see the time displayed through the ruby red

glass

especially knowing that the watch is running with my new PLT-1 module. I am

going to send one of these watches to my dad, but I don't think he remembers any

of this. We shall see....

I really enjoyed this project, I would have liked to have more time and to have

done it a lot quicker, but that's the way it goes. I have already started work

on the next project. A replacement module for the Pulsar P4 Wrist Flick

Executive and Dress Model LED watch. Other replacement modules are in the

pipeline. "LED Watch this space!" Get it ;-)

If you would like to support our work and get your un-fixable watch fixed,

please visit the PLT-1

Replacement Pulsar LED Watch Module Page for further details.

Visitors To This Page Since 11 March 2013.

|